FAQ - Interim guidance on the revision of the Monitoring Plan

The following questions and answers are intended to serve as interim guidance to support shipping professionals in understanding the application of the MRV Maritime Regulation. They do not replace the legislation. For further details, please consult the updated MRV Maritime Regulation.

Latest update: 19 February 2024

1. Can a third company, different from the registered owner or the mandated ISM company, be indicated as Company in the Monitoring Plan (see Table B.2 of the template)?

No, only the ‘shipping company’ (i.e. the registered owner or mandated ISM company) assuming responsibility for both MRV and EU ETS compliance can be indicated as the ‘Company’ in Table B.2 of the Monitoring Plan template.

2. Who should be indicated as ‘Contact Person’ in the Basic Data section of the Monitoring Plan?

The information provided about the ‘Contact person’ will help the Administering Authority to establish direct contact for any questions about the Monitoring Plan. The contact person for the ‘shipping company’ should notably be a person authorised to act on behalf of the ‘shipping company’ (i.e., the entity assuming responsibility for MRV and EU ETS compliance) and should be accessible by the Administering Authority. An additional contact person, such as someone working for a third party assisting the ‘shipping company’ in fulfilling its monitoring and reporting obligations (i.e., a contact within the technical manager or bareboat charterer), can be indicated in the ‘Additional information’ section under the ‘Further info.’ tab within the Monitoring Plan page of THETIS MRV.

3. Which emissions sources must be listed in the Monitoring Plan?

Under the MRV Maritime Regulation, the monitoring and reporting must be complete and cover greenhouse gas emissions from the combustion of all fuels. Therefore, all emissions sources onboard the ship must be listed and described in the monitoring plan, irrespective of the amount of emissions produced over the reporting period.

To better cater for this, the list of standard emissions source types has been expanded following the adoption of Commission Implementing Regulation (EU) 2023/2449. For instance, it now also includes ‘Fuel cells’, ‘Waste incinerators’, and the category ‘Other’, to cover any other emissions source type.

4. Which fuel types must be listed in the Monitoring Plan?

The shipping company must list all fuel types applicable over the reporting period. Accordingly, the Monitoring Plan must specify, in line with Table B.3 of the template, each emissions source type the shipping company plans to apply over the reporting period for each of its ships. The list of fuel types has been expanded following the adoption of Commission Implementing Regulation (EU) 2023/2449, and now also includes: ‘H2 (Fossil)’, ‘NH3 (Fossil), ‘Methanol (Fossil)’, ‘Ethanol’, ‘Bio-diesel’, ‘Hydrotreated Vegetable Oil (HVO)’, ‘Liquified bio-methane as transport fuel (Bio-LNG)’, ‘Bio-methanol’, ‘Other Biofuel’, ‘Bio-H2’, ‘e-diesel’, ‘e-methanol’, ‘e-LNG’, ‘e-H2’, ‘e-NH3’, ‘e-LPG’, ‘e-DME’, and ‘Non-fossil Other fuel’.

5. How should fuel blends be considered in the Monitoring Plan?

Where there is fuel blending, each component of the blended fuel must be considered as a separate fuel, as per Annex I to the MRV Maritime Regulation. The Monitoring Plan should therefore list separately all the relevant fractions of a blend, indicated as pure fuels. The list of fuel types as in point 2, Part A, of Annex I to the MRV Maritime Regulation, covers an extensive range of potential fuel types for application onboard a ship. The possibility to report a different fuel type is restricted to ‘Non fossil other fuel type’ not matching any of the types listed in point 2.

6. Which emission factors should be listed in the Monitoring Plan?

The shipping company must identify the emission factor to be applied to each fuel type applicable over the reporting period (see 4th question). As a general rule, the shipping company should apply the default (tank-to‑wake) emission factor values listed in Annex I to the MRV Maritime Regulation, which cover those applicable to both fuel combustion (for CO2, CH4, N2O) and slippage (Cj values). The possibility to provide actual emission factors diverging from the default ones can still be pursued in accordance with the conditions and restrictions provided in Annex I to the MRV Maritime Regulation, which refers to Article 10, paragraphs (5) and (6) of Regulation (EU) 2023/1805 (‘FuelEU Maritime Regulation’). That Article requires actual emission factor values to be “certified by means of laboratory testing or direct emissions measurements” in accordance with rules to be laid down in an implementing act. Such conditions and restrictions are currently under development and, until their finalisation, shipping companies are required to apply default emission factor values (see 8th question).

7. Is it possible to use an actual CO2 emissions factor different from the default ones for fossil fuels?

No. Annex I to the MRV Maritime Regulation, through the reference to Article 10(5) of the FuelEU Maritime Regulation, does not allow to apply actual emission factor values for the tank-to-wake CO2 emission factors for fossil fuels.

8. What are the conditions for demonstration of actual emission factors applicable within the MRV Maritime Regulation?

The implementing acts foreseen under Article 10(6) of the FuelEU Maritime Regulation will specify which international standards and certification references are accepted for demonstration of actual tank-to-wake emission factors. Those could be complemented by further guidance developed for application within the framework of the MRV Maritime Regulation. Until the moment the relevant international standards and certification references are specified, shipping companies are required to apply default emission factor values.

In case a company wishes to demonstrate actual emission factors, the procedures, systems and responsibilities used for this purpose must be documented in accordance with Table B.8 of the Monitoring Plan template.

9. Is it possible to demonstrate actual slippage coefficients values?

Within the MRV Maritime Regulation, slippage coefficients are defined as emission factors. Therefore, the same conditions and restrictions as the ones for the demonstration of actual emission factor values described above apply (see 6th and 8th questions). Specific guidance is expected to be provided on the applicable procedures for the demonstration of actual slippage coefficients. Until then, companies should apply the default slippage coefficient values listed in point 2, Part A, of Annex I to the MRV Maritime Regulation.

10. How should a company determine the emissions to be reported within the EU ETS scope?

The shipping company must first determine emissions to be reported within MRV scope by applying the formulas established in Part A of Annex I to the MRV Maritime Regulation. The results of the application of the formulas must serve as a basis for the determination of the emissions within EU ETS scope, through the application of the calculations set out in Part C of Annex II, as relevant. When submitting emissions data in THETIS-MRV, users can categorise emission records based on various distinguishing criteria, including those associated with MRV legal frameworks and others linked to the EU ETS legal framework. The system will then generate the annual aggregation relevant to both MRV and EU ETS, based on the chosen distinguishing criteria.

For information on the differences between the scope of MRV and EU ETS, see the question “To which emissions does the EU ETS Directive apply?” and the section “Specific rules and derogations” on our FAQs page.

11. Is it possible to apply an emission factor of zero to sustainable biofuels for the determination of emissions within MRV scope?

No, since emission factors are based on a tank-to-wake approach, zero-rating is not an option for emissions within the scope of the MRV Maritime Regulation.

However, the zero-rating of the CO2 emission factor is foreseen by the derogation established under point 1.2, Part C, of Annex II to the MRV Maritime Regulation, which establishes the rules for the determination of emissions within EU ETS scope. In practice, the consumption of the same fuel batch may result in emissions to be reported under MRV while accounting for zero emissions under the EU ETS. In case a company wishes to apply the derogation established in point 1.2, Part C, of that Annex II, the procedures, systems and responsibilities used for this purpose must be documented in accordance with Table B.9 of the Monitoring Plan template.

12. Is it possible to attach any document to the Monitoring Plan?

Users can attach a set of documents to the Monitoring Plan in THETIS MRV, including the mandatory assessment report issued by the verifier (as required by Article 73 of Commission Delegated Regulation (EU) 2023/2917) and a copy of the mandate to be provided in line with Commission Implementing Regulation (EU) 2023/2599 (when applicable). Once attached to the Monitoring Plan of a ship, such documents will be available to relevant users in the Monitoring Plan workflow established in the system, including Administering Authorities. Links to external servers do not qualify as accepted attachments to the Monitoring Plan and may be disregarded by the Administering Authorities.

13. When describing a procedure in the Monitoring Plan, can the shipping company simply include a reference to external sources?

By default, the monitoring plan shall include a description of the relevant procedures. Notably, the complete procedure itself does not have to be included. This is to ensure flexibility in cases where smaller details of the procedure can change frequently (e.g. the name of the responsible person) and such minor changes do not justify an update of the monitoring plan. The description in the monitoring plan must be sufficiently detailed to allow the verifier and the administering authority to understand the procedure.

Simple procedures will be completely reflected by the description. However, when the procedure is more elaborated, it may be established and described in an external source (such as a written procedure or harmonised quality, environmental or energy management standards). In the latter case, a brief description will suffice, although it should contain a reference to the full procedure and indicate where its full version is stored. In any case, the shipping company will have to grant access to such external sources to the verifier or the Administering Authority upon their request.

14. What can be considered as a written procedure within the Monitoring Plan?

“Written procedures” are meant to supplement the Monitoring Plan as explained under Question 13. The shipping company must establish, document, implement and maintain these for activities under the monitoring plan. Article 6(3) of the MRV Maritime Regulation requires procedures for the following purposes:

- Regular updating the list of emission sources onboard each ship;

- Monitoring of the completeness of voyages;

- Monitoring fuel consumption of the ship, including for the measurement of fuel uplifts and fuel in tanks, and density, if applicable;

- Determining activity data per voyage (distance, passengers and cargo carried, time spent at sea between port calls, and if applicable, also the distance travelled and the time spent at sea when navigating through ice);

- Determine surrogate data for closing data gaps.

Furthermore, Part C of Annex I to the MRV Maritime Regulation requires written procedures for the purpose of describing data flow activities, the risk assessment, and control activities, and for avoiding data gaps. Such written procedures may be contained in full in the Monitoring Plan or described through references to external written procedures (see previous question).

15. What is a control system?

A control system sets measures that help minimise risks. A well-functioning control system helps to comply with monitoring and reporting principles within the EU ETS, namely: completeness, consistency, comparability, transparency, accuracy, integrity and continuous improvement.

In accordance with Part C of Annex I to the EU MRV Maritime Regulation, the control system for shipping companies must consist of the following elements:

- Written procedures for data flow activities;

- Risk assessment;

- Written procedures for control activities.

A control system should not be rigid, but dynamic. The shipping company is required to monitor the effectiveness of the control system, including by carrying out internal reviews and considering the findings of the verifier during the verification of emission reports.

When a company finds the control system ineffective or not commensurate with the risks identified, it must seek to improve it and update the monitoring plan or the underlying written procedures for data flow activities, risk assessments and control activities accordingly.

16. What is included in the written procedures of a control system?

The shipping company is required to establish, document, implement and maintain written procedures, for data flow activities as well as for control activities. This must be done separately from the Monitoring Plan.

Written procedures for control activities must at least include:

- Quality assurance of the measurement equipment;

- Quality assurance of the information technology system;

- Segregation of duties in the data flow activities and control activities, and management of necessary competencies;

- Internal reviews and validation of data;

- Corrections and corrective action;

- Control of out-sourced processes;

- Keeping records and documentation, including the management of document versions.

The updated template for the Monitoring Plan (implemented in THETIS MRV) provides the relevant fields for the description of these procedures.

17. What are the first steps to follow when setting up a control system?

As a first step, the shipping company creates the data flow providing a logical sequence of data collection and processing steps. Then, the shipping company must carry out a risk assessment to identify sources of risks of errors in the data flow from primary data (e.g. in case the engineer performs manually daily tank soundings) to final data in the annual emissions report (e.g. aggregated data from an IT system).

Thereafter, the shipping company must establish, document, implement and maintain written procedures, separately from the monitoring plan, for data flow activities as well as for control activities. The company must also describe those procedures and include references to them in the monitoring plan. The effectiveness of the control system is to be monitored and, when necessary, the procedures need to be improved.

18. What are data flow activities in the context of GHG emissions monitoring?

Monitoring of emissions data implies more than just reading instruments or carrying out chemical analyses. For the monitoring and reporting of greenhouse gas emissions, it is important for shipping companies to ensure that data is retrieved, collected, transported and stored in a controlled manner.

Therefore, the shipping company must define instructions on ‘who takes data from where and does what with it’. These ‘data flow activities’ are laid down in written procedures accompanying the Monitoring Plan, which must be made available to the verifier and the Administering Authority upon request. The shipping company must describe those written procedures and include references to them in the Monitoring Plan.

When the shipping company starts designing the Monitoring Plan, it creates the data flow providing a logical sequence of data collection and processing steps. As errors may occur in the obtaining or transmission of data, an effective control system is necessary, as explained in the questions and answers below.

19. Where can I find detailed information on data flows, risk assessment and control activities?

The relevant provisions for shipping companies, as amended through Commission Delegated Regulation (EU) 2023/2776, are closely aligned to those applicable to stationary installations and aircraft operators contained in Commission Implementing Regulation (EU) 2018/2066. Therefore, the Guidance Document No. 6: ‘Data flow activities and control system’, can be used by shipping companies to access detailed information on these topics. The document is almost directly applicable to the maritime transport sector and, for that purpose, ‘operator’ and ‘aircraft operator’ should be read as ‘shipping company’.

20. How can data flows be described?

Data flows can be described in writing in different forms. For simple data flows, a short description may be sufficient, while in complex cases a data flow diagram will be indispensable. Furthermore, detailed checklists for each department involved and training material for staff may need to be developed.

Examples of how data flows can be described:

- Data flow diagram

- Task list

- Written procedures

- Check lists and lists of incidents or deadlines triggering activities.

Examples of these different data flows can be found in MRR Guidance Document No. 6: Data flow activities and control system (see also previous question).

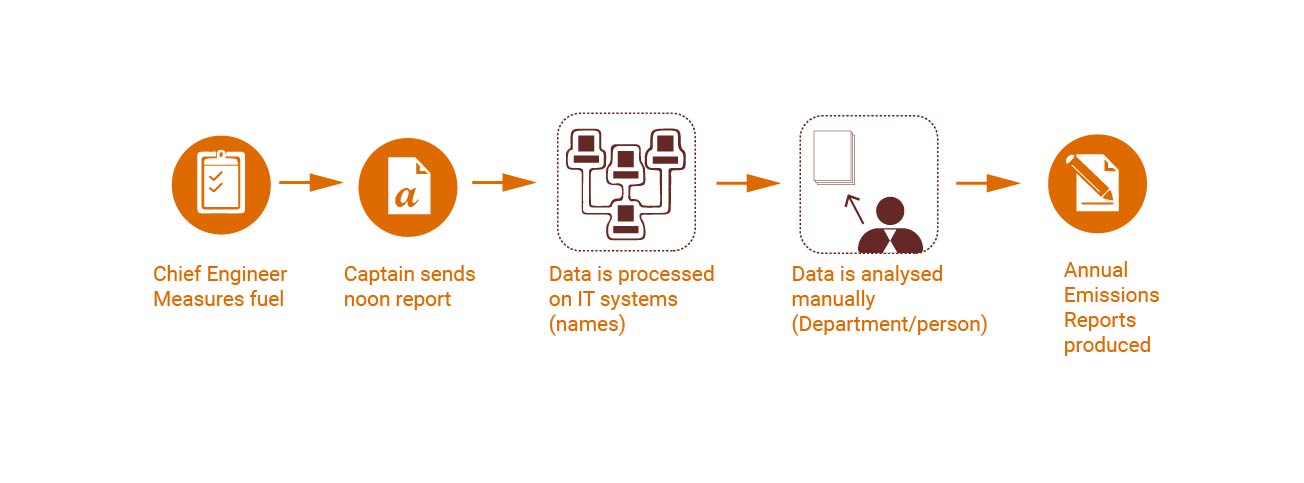

21. Example of a data flow diagram concerning fuel quantity

A data flow diagram is often a useful tool to assess and/or set up data flow procedures.

Here is an example with the information about the procedure alongside a diagram: The Captain receives information from the Chief Engineer after taking the soundings of the fuel tanks using sounding tape, then he inserted into the daily noon report.

Please note that it is not always necessary for a data flow diagram to contain pictures. However, data sources, data storage, and any processing steps, such as the monthly summation of data, need to be clearly identified.

22. Why are risk assessment and control activities required?

As human beings (and, in many cases, different information technology systems) are involved, mistakes in data flow activities can occur. Therefore, a control system is necessary. Both the risk assessment and control activities are part of a well-functioning control system, allowing the verifier to carry out more efficient verification activities. Both must be described in written procedures supplementing the Monitoring Plan.

23. What is the purpose of the risk assessment?

A risk assessment is the first step to follow when establishing a control system. It helps the shipping company to identify points in the data flow where control activities are needed, and where they can be applied more effectively. The shipping company should regularly update its risk assessment, adapting it to relevant changes (e.g. to the ship configuration or to new IT systems).This may lead to the identification of new risks and a need to update the control procedures as well (see last question).

Please note that Article 15(1) of the MRV Maritime Regulation requires the verifier to carry out a risk analysis. Such risk analysis, however, is distinct from the risk assessment to be carried out by the shipping company pursuant to Part C of Annex I to the MRV Maritime Regulation, since its purpose is to support the verifier with the identification of necessary verification activities.

24. What does ‘risk’ for a shipping company mean in the context of MRV?

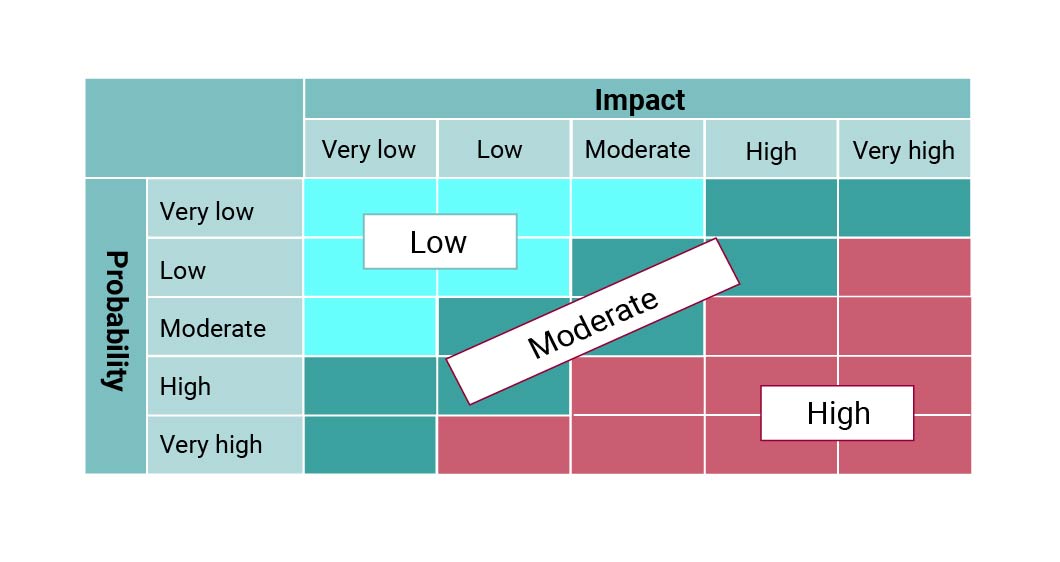

‘Risk’ (R) is a parameter which takes into account both the probability (P) of an incident and its impact (I). In terms of emissions monitoring, the risk refers to the probability of a misstatement (omission, misrepresentation or error) being made, and its impact in terms of annual emission figures.

To simplify, it can be said that R = P × I.

Therefore, if either probability or impact is high, the risk will be high as well, unless the other parameter is very low. Where probability and impact are high, the risk will be very high, as indicated in the following figure.

There are two different kinds of risks that are relevant for the shipping company:

- ‘Inherent risk’ (IR) refers to the susceptibility of a parameter in the shipping companies’ report to misstatements that could be material, individually or when aggregated with other misstatements, before taking into consideration the effect of any related control activities.

- ‘Control risk’ (CR) refers to the susceptibility of a parameter in the shipping companies’ report to misstatements that could be material, individually or when aggregated with other misstatements, which will not be prevented or detected and corrected on a timely basis by the control system.

As long as humans are involved, errors will happen. The inherent risk reflects the fact that MRV is carried out by human beings, and that therefore errors can simply happen. The control risk reflects the quality of the control system. The more effective the shipping companies’ control system is, the lower is the control risk, i.e. the likeliness for a failure to prevent errors.

The inherent risk is to be reduced as much as possible by choosing robust data sources and short and simple communication paths. The control risk is minimised by setting up effective control activities.

25. What steps are shipping companies required to take after carrying out the risk assessment?

Once the shipping company has assessed the risks associated with its data flow, the second part of the control system must be established, i.e. appropriate control activities to mitigate the identified risks. A typical example of control activity is the four-eyes principle, i.e. the review of data/information/reports by an independent second person. The shipping operator can establish that it should at least be applied to the overall annual emissions report (in analogy to the independent review of the verifier). Other examples of control activities are: keeping backups of data in IT systems, data quality checks like trend analyses or data completeness checks, or checking (calibrating) measurement instruments at regular intervals.

In a next step the shipping company must assess the risks (now mitigated) once more to determine if the control measure will be effective and applied properly.

This is an iterative process. If the result is not satisfactory, the shipping company will have to take a step back and re-develop its control activities. In some cases it might be necessary to go back to the early steps of monitoring plan development, selecting more appropriate data sources or rearranging the data flow in a sequence which is less prone to errors.

The Commission and the European Maritime Safety Agency are available to answer any queries from stakeholders in relation to the new requirements under the revised MRV Maritime Regulation and the EU ETS Directive. Please contact fitfor55@emsa.europa.eu for any question you may have. You may also find this text replicated on the web page of the Directorate-General for Climate Action at the European Commission.